About Us

Introduction

PASSER SIDC is a major EPCI company within manufacturing of offshore foundations, shipbuilding and modernization as well as project management. The main focus of the company's activity is the renewable energy industry with a vision of a cleaner, better future for the coming generations.

PASSER SIDC is a part of PASSER Group and is the fabrication capacity for all types of cable handling equipment delivered by PASSER Group to the energy industry. The key areas also include industry, steel structures and engineering. A team of professionals implements complex projects from design to product documentation.

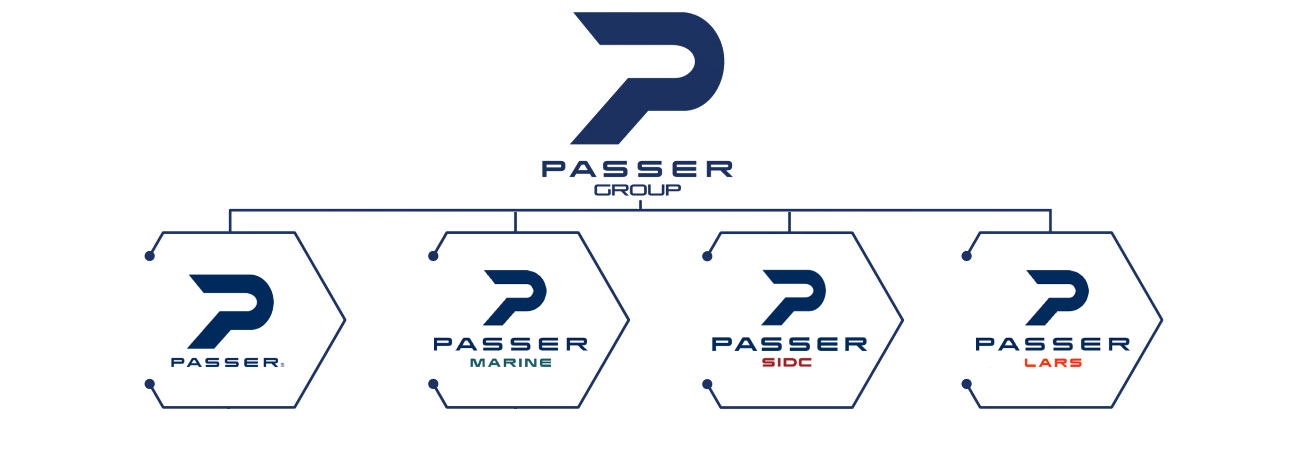

PASSER Group is a leading industrial group of companies focused on providing solutions for the renewable energy sector. The portfolio includes equipment and services for offshore cable handling & manufacturing, metal fabrication, shipbuilding and cryogenic insulation.

Visit PASSER Group here.

PASSER SIDC key areas of specialization: cable handling equipment, shipbuilding and modernization, manufacture of industry and steel structures, project management, engineering and more.

PASSER SIDC manufacturing sites are currently located at Klaipeda Seaport. The construction of a new manufacturing plant has begun. This new area will allow us to meet growing customers‘ needs.

Large scale projects implemented by our professionals are not limited to shipbuilding and ship repair: they also include oil and gas, wind power station, and civil engineering sectors.

PASSER SIDC clients include leading enterprises such as: Royal Bodewes shipyard, RAUMA, Meyer Turku, Terastorni Oy, MS Steel Oy, GE Oil & Gas Uk Ltd., Strohm B.V., Bexco NV, Baker Hughes Energy Technology UK Ltd., JDR Cables Systems Ltd., Aker Solutions, Nexans SA, NKT Cables GmbH, Metsä Fibre Oy, ENGIE Solutions, Damen ship repair harbour & voyage, Brunton Shaw UK, Subsea7, Oceaneering, Technip Flexy France (TFF) and others.

The geography of our projects, completed or underway, include Lithuania, Belgium, the Netherlands, the Nordic countries, Estonia, Slovenia, France, Germany, and Brazil.

Our capacities and competences of our personnel enable us to deliver turnkey projects to our customers.

The international team of PASSER SIDC consists of more than 300 professionals from Lithuania, Estonia, Ukraine, and Romania, including project managers, engineers, electricians, insulation installers, technicians, painters/sandblasters, pipework installers, welders, shipbuilders, and high-rise workers.

PASSER SIDC, UAB

The company is successfully operating in the industry of metal structure and pipework production.

PASSER SIDC Group, UAB

Management company of PASSER SIDC group of partners.

PASSER SIDC Projects, UAB

A ship repair and ship-building

company, a member of SIDC

Partner Group.

ASA RENT, UAB

Transport rental & internal logistics company of the group.

We have ISO 9001, 14001, and ISO 45001 management system certificates and VCA* certificates:

PASSER SIDC is included in the list of the 500 strongest companies in Lithuania of 2022. The list was compiled by the most famous Lithuanian business portal and is a great evaluation of sustainable growth and operational efficiency.

History

SIDC founded

First contracts awarded for employee leasing and main pipework

First contracts awarded for production of metal structures and subcontractor activities. NEN 4001 certification

1 million Euro annual turnover

Production established

High-rise works started

ISO 3834, ISO 1090, 9001, 14001, and 18001 certification

Start of production of metal structures in non-standard sizes, ship repairs, shipbuilding, and off-shore products. ISO 1090

4 million Euro annual turnover

SIDC LT training centre established to enable our personnel to improve their knowledge or gain required competences as needed

First turnkey contract awarded

7 million Euro annual turnover

Aukscio Specialistai UAB and Skandinavijos Projektai UAB founded

SIDC LT group company Olandijos technine konsultacija UAB gains certificate Strongest in Lithuania 2016

11 million annual turnover

Corporate branding renewal

NEN 4400 certification in Netherlands

First project in Belgium

12 million annual turnover

First ship builded by SIDC reaches the sea

17,5 million annual turnover

Annual turnover 32M

RINA certification

SIDC LT becomes a part of PASSER group.

PASSER SIDC is included in the list of the 500 strongest companies in Lithuania for the first time.

PASSER SIDC becomes a part of Lithuanian Maritime Cluster.

Construction of a new workshop starts.

First major project in Uruguay starts.

PASSER SIDC together with a partner acquires shipyard in Netherlands.

The contract on the construction of two unmanned ships is signed.

QUALITY, ENVIRONMENTAL PROTECTION AND OCCUPATIONAL SAFETY/HEALTH MANAGEMENT POLICY

PASSER SIDC GROUP, UAB, belonging to and related companies using advanced technological processes, carries out production and assembly of steel and non-steel structures for civil and industrial construction; production and installation of high pressure piping systems; metal constructions’ repair and welding at height for offshore projects, ensuring high quality of the products produced and fulfilment of orders within the set deadlines, based on the wishes and documentation submitted by the customers, and in line with requirements of legal acts and other applicable documents, as well as provides other production services.

Our strategic goal is a stable development of the Company and environmentally friendly production creating the conditions for continuous improvement in the quality of the Company management aimed at maintaining the level of competitiveness of our products and services.

Based on the principles of international standards ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, the management of PASSER SIDC GROUP, UAB establishes the integrated Policy as follows:

- Strengthen the trust of our consumers, employees, shareholders, investors, product and service providers and the public in the Company through the knowledge and understanding of their needs and tasks, as well as systematic assessment and enhancement of their satisfaction level;

- Develop an environment in which every employee would be interested in: improving the quality of their work, complying with the requirements of work safety and environmental protection procedures established by legal acts and the Company;

- Regularly analyse and evaluate the relevance of activities relating to our current and planned Quality, Environmental Protection and Occupational Safety System, and continuously improve its effectiveness;

- Protect natural resources, implement pollution prevention actions, follow provisions of legal acts and applicable standards, adhere to procedures established by the Company and maximize our contribution to global climate change mitigation.

- Base decisions on logical analysis of reliable data, obtained through monitoring and measurement of specific product characteristics, processes, environment and production environment;

- Build relationships with our users, suppliers, investors and partners on the basis of mutually beneficial cooperation and the priorities according to the strategic goals of the Company.

- Systematically identify training needs, as well as encourage involvement of employees in the Quality, Environmental Protection and Occupational Safety Systems.

- Identify measurable indicators of the occupational safety and health management system, carry out measurements and accumulate measurement results, control them according to permissible standards and manage the implementation of the decisions made at economically efficient costs, and mitigating the identified occupational safety risks;

- Provide opportunity for employees to report to the management of inadequate working conditions, accidents and events that may have resulted in an accident at work;

- Ensure opportunity for all employees of the Company to consult on the safety and health issues and allow them to participate in this process;

- Improve the working conditions and eliminate the hazards by reducing risks at work, continuously improving prevention methods for risk assessment and occupational diseases, accidents and other incidents;

- Ensure the efficient operation of the working environment, occupational safety and health management system so that the employees would be satisfied with their work, working environment and team relations.

- To protect the health of our employees, customers and communities in case of pandemic and to ensure immediate compliance with governmental and health authorities’ regulations and recommendations; to ensure that and appropriate and effective response plan is developed and implemented.

Aivaras Kamas

Director of PASSER SIDC GROUP, UAB

2022-10-10